To meet the Thai client’s inquiry on prefab house frame fabrication details, our factory team completed 3 sets of frame samples on-site, with the whole process recorded and shared with the client who expressed great satisfaction afterward.

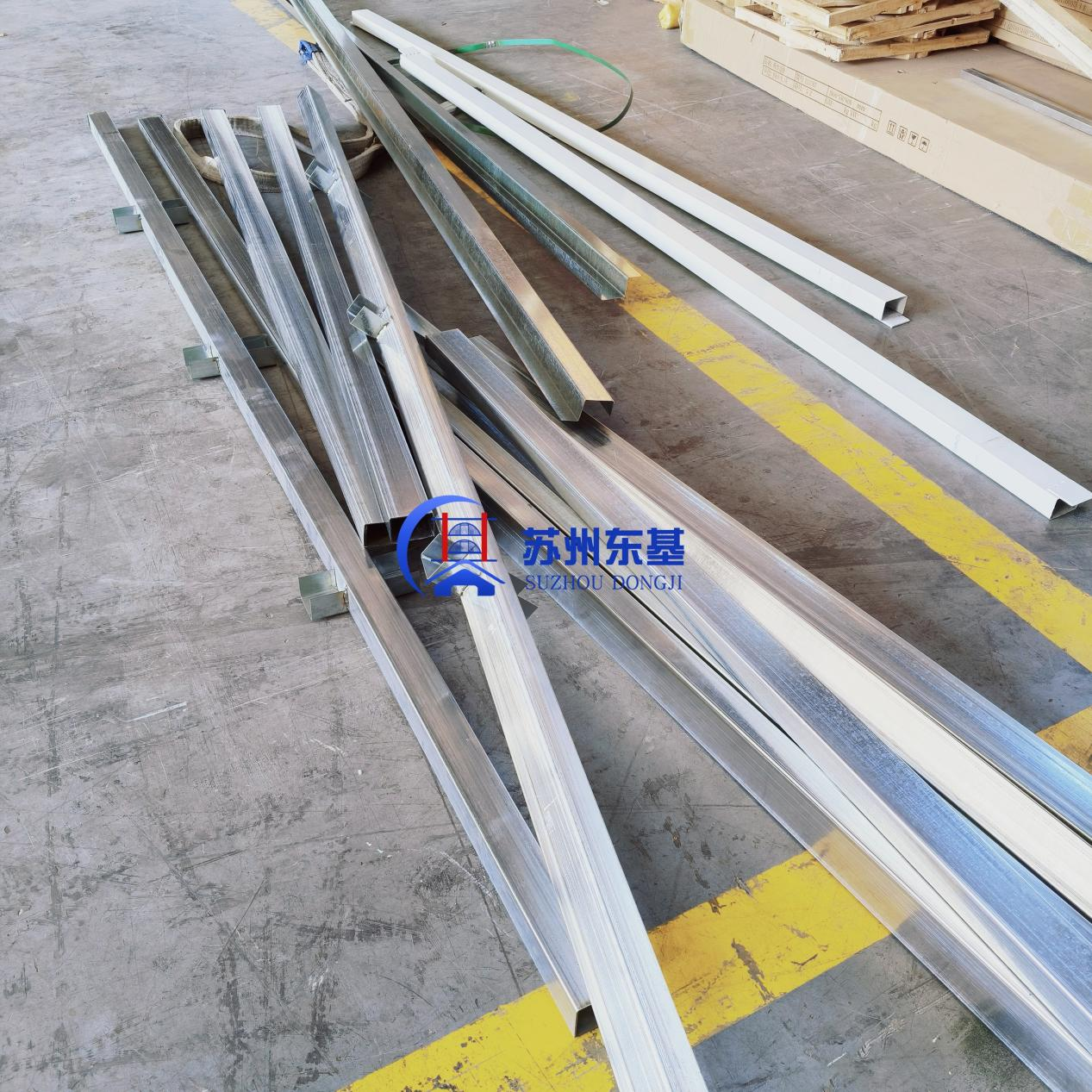

The 3 frame samples cover diverse specifications to match different prefab house demands: 1 standard flat pack frame (5.95m3m2.8m) and 2 triangle frames (5.95*3*3.95m, 5.95*3*3.2m) respectively.

Responding to the client’s core concerns about the assembly process, we confirm key details as follows: the whole assembly was finished by only 4 workers within 30 minutes, with electric hand drill as the core tool. The streamlined process reflects our mature fabrication system and skilled team capability, ensuring high efficiency while maintaining structural precision of prefab frames.

After receiving the on-site assembly video, the Thai client highly recognized our professional strength and efficient execution, showing strong positive feedback on the sample quality and fabrication efficiency.

We will keep optimizing prefab house component production and assembly processes, providing more reliable products and clear technical display for global clients, and supporting clients’ project development with professional solutions.

Hot News

Hot News2026-02-25

2026-02-10

2026-02-05

2026-01-30

2026-01-21

2026-01-19