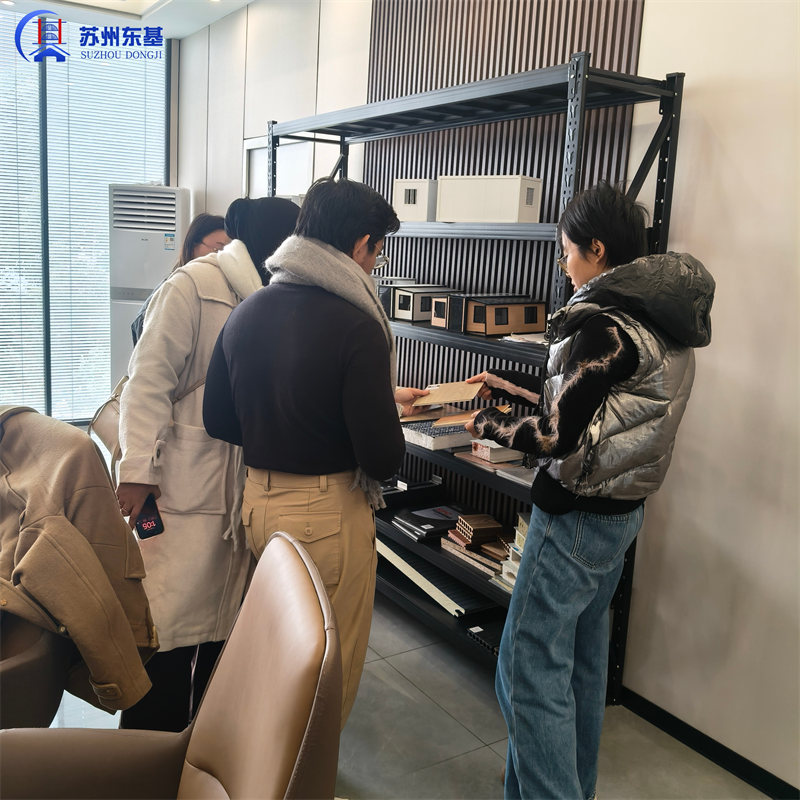

Recently, a renowned Malaysian enterprise client made a special trip to China to visit the prefabricated house production base of Suzhou Dongji. The visit originated from in-depth communication between the two parties on the Alibaba platform. As a professional supplier of prefab building solutions for the Malaysia market, Suzhou Dongji proposed a customized plan tailored to the client's worker accommodation needs. After on-site factory inspection, sample testing, and technical exchanges, the dual-size prefab dormitory solutions (3*8m and 4*9m) have won high praise from the Malaysian client for their personalized appearance design, strict waterproof standards, long service life, and efficient production capacity guarantee, laying a solid foundation for in-depth cooperation between the two parties.

Precisely Meeting Needs: Custom Prefab Dormitories Solve Malaysia's Accommodation Pain Points

The core demand of the Malaysian client focuses on the practicality and comfort of worker accommodation. They clearly required an overall structure with 3 independent living units per floor and two floors in total. Each prefab unit will be equipped with 2 beds and a bathroom, separated by a partition to form two independent small spaces. Targeting this typical collective accommodation demand in the Malaysia market, the engineering team of Suzhou Dongji precisely planned the spatial layout, maximizing comfort while ensuring living density, perfectly adapting to multi-person collective living scenarios.

In terms of appearance design, the client particularly emphasized "de-containerization" and pursued a visual effect that combines personalization and aesthetics. Suzhou Dongji recommended metal carved panels as the external decorative wall panels. This material not only offers a variety of color options and three-dimensional textures, allowing for customized appearance styles according to the Malaysian client's preferences, but also integrates multiple advantages such as thermal insulation, fire resistance, and weather resistance, adapting to the local climate in Malaysia. The on-site displayed samples allowed the client to intuitively feel the texture and appearance of the metal carved panels, completely eliminating concerns about the monotonous look of prefab houses and confirming the adoption of this plan on the spot.

Why Are Prefab Houses the First Choice for Malaysia Cross-border Procurement?

As an innovative form in the modern construction field, prefab houses, with their core model of "factory prefabrication and on-site assembly", have become the preferred solution for industrial accommodation supporting facilities in Malaysia. Their advantages are fully reflected in Suzhou Dongji's products:

- Efficient Construction + Mass Production Capacity, Adapting to Malaysia's Bulk Demand: All components are produced in a standardized manner at Suzhou Dongji's factory, with a daily production capacity of 500 units, enabling rapid response to the bulk procurement needs of Malaysian clients. Meanwhile, the on-site assembly efficiency is far higher than that of traditional construction models, shortening the construction period by 30%-50%, significantly reducing the on-site construction costs and time costs for Malaysian clients, and accelerating the investment return cycle.

- Controllable Quality, Safety and Durability: Relying on a factory-based production environment and a strict quality control system, the structural strength error of Suzhou Dongji's prefab houses is controlled within millimeters, far exceeding traditional process standards. The product is designed with a service life of 50 years, fully meeting the core demand of Malaysian clients for long-term use of residential buildings. Additionally, through multiple anti-corrosion and anti-rust treatments, it is suitable for Malaysia's hot and humid climate.

- Green and Environmentally Friendly, Cost Optimization: The prefabricated construction model reduces on-site wet work and construction waste emissions. Compared with traditional construction, it can reduce 60% of construction waste and 20% of carbon emissions, in line with Malaysia's green development policy trends. Centralized production and procurement can also effectively control material loss and labor costs, helping Malaysian clients achieve maximum cost-effectiveness.

- Flexible Customization, Adapting to Diverse Needs: Whether it is the compact 3*8m layout or the spacious 4*9m layout, Suzhou Dongji can provide personalized designs according to the spatial needs, functional configurations, and appearance preferences of Malaysian clients. The application of new materials such as metal carved panels can achieve a customized effect of "both appearance and strength".

Addressing Core Concerns: Strict Standards Build a Solid Defense Line for Waterproofing and Durability

Targeting the waterproofing issue that the Malaysian client focuses on, Suzhou Dongji has implemented comprehensive protection from the source of design: the roof adopts a composite structure of double-layer waterproofing membrane and profiled steel plate, with joints fixed by sealing strips and pressure strips to prevent rainwater infiltration; the bottom is equipped with a moisture-proof elevated layer, combined with waterproof coating and drainage system, effectively isolating ground moisture and rainwater intrusion, ensuring a dry and comfortable living environment, and perfectly coping with Malaysia's rainy climate. The on-site waterproofing test demonstration allowed the client to intuitively witness the product's waterproof performance, completely eliminating their concerns.

"We not only pay attention to the immediate use effect of the product, but also value long-term stability, which is one of the core reasons why Malaysian clients choose us," said the person in charge of Suzhou Dongji. All prefab houses of the company comply with the "Technical Standard for Prefabricated Buildings" GB/T 51231-2025. Core components have undergone multiple inspections such as load testing and weather resistance testing, with full traceability from raw materials to finished product delivery, ensuring the safety and durability of the building throughout its life cycle with strict standards.

About Suzhou Dongji: Preferred Supplier of Prefab Houses in Malaysia

Suzhou Dongji is a high-tech enterprise specializing in the R&D, production, and sales of prefab houses and modular buildings. It has a modern production base and a professional R&D and design team, with a daily production capacity of 500 units and strong bulk delivery capabilities. The company's products cover a variety of categories including prefab dormitories, offices, and storage rooms. With standardized production, personalized customization, and global service capabilities, it has provided high-quality building solutions for clients in many countries and regions including Malaysia.

Relying on cross-border e-commerce platforms such as Alibaba, Suzhou Dongji actively expands overseas markets including Malaysia, always taking "customer demand as the core" and regarding product quality and service experience as core competitiveness. The successful on-site visit of the Malaysian client not only demonstrates the company's product strength, technical advantages, and production capacity guarantee, but also confirms the broad prospects of prefab houses in the Malaysia cross-border procurement market. In the future, Suzhou Dongji will continue to deepen its presence in the prefab construction field, providing more efficient, environmentally friendly, and durable customized building solutions for Malaysian and global clients.

Hot News

Hot News2026-01-30

2026-01-21

2026-01-19

2026-01-16

2026-01-15

2026-01-09