As the global construction industry shifts toward efficiency and sustainability, modular (prefabricated) houses have gained widespread popularity for their fast assembly, low waste, and energy-saving advantages. Among the key components that determine a prefabricated house’s performance—especially in insulation, soundproofing, and durability—wall panels play a critical role. However, many consumers and even industry newcomers remain unfamiliar with the common types of wall panels used in modular housing and their unique functions. To address this gap, we break down the three most widely adopted wall panel materials in the sector:

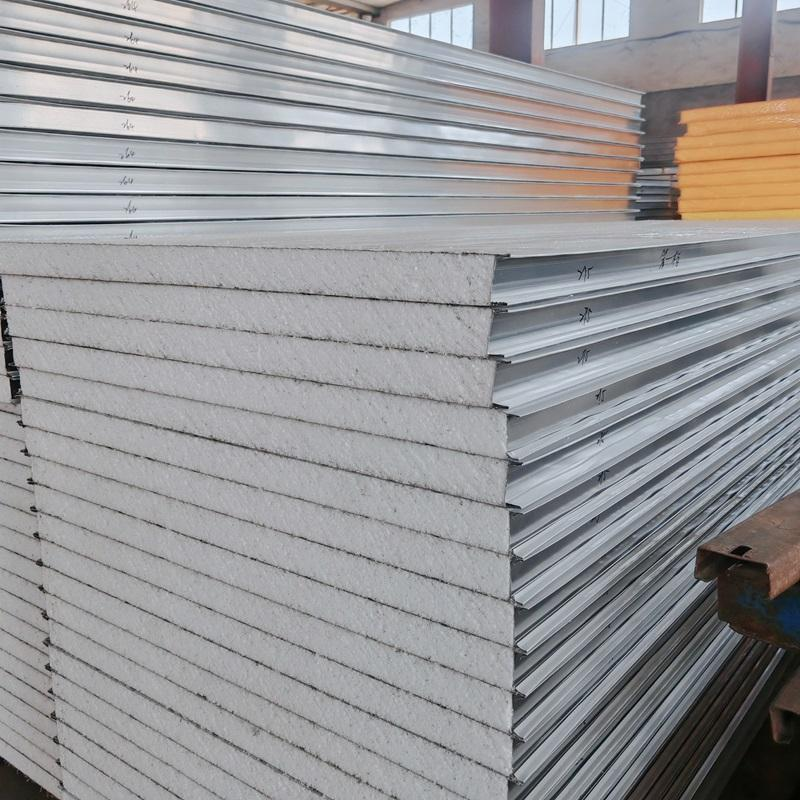

1. EPS Wall Panels

EPS (Expanded Polystyrene) wall panels are a staple in modular housing, favored for their lightweight design and excellent thermal insulation. The core of these panels is made of expanded polystyrene—a closed-cell foam that effectively traps air, reducing heat transfer between the interior and exterior of the house. This makes EPS panels ideal for regions with extreme temperatures, as they help lower heating and cooling costs. Additionally, EPS panels are easy to cut and install, which speeds up the construction process, and their low cost makes them a cost-effective choice for mid-range modular housing projects.

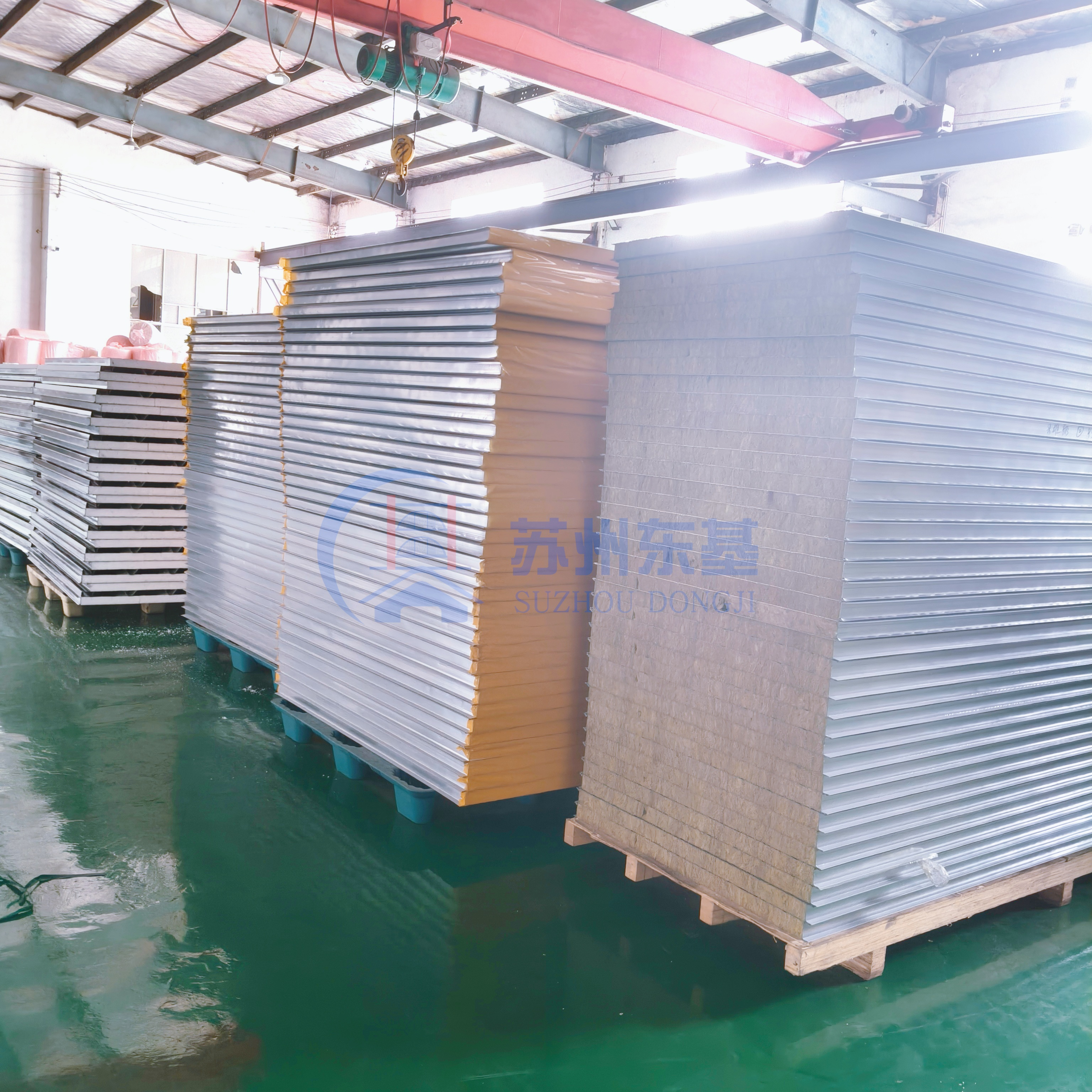

2. Rock Wool Wall Panels

Rock wool (or mineral wool) wall panels stand out for their exceptional fire resistance and soundproofing capabilities. Made from melted volcanic rock or basalt, which is spun into fibers and pressed into panels, rock wool is non-combustible and can withstand high temperatures (up to 1,000°C in some cases). This makes it a top choice for modular houses in areas with strict fire safety regulations, such as commercial modular buildings or residential projects near wildfire-prone regions. Beyond fire protection, rock wool’s dense fiber structure also absorbs sound waves effectively, minimizing noise from outside the house.

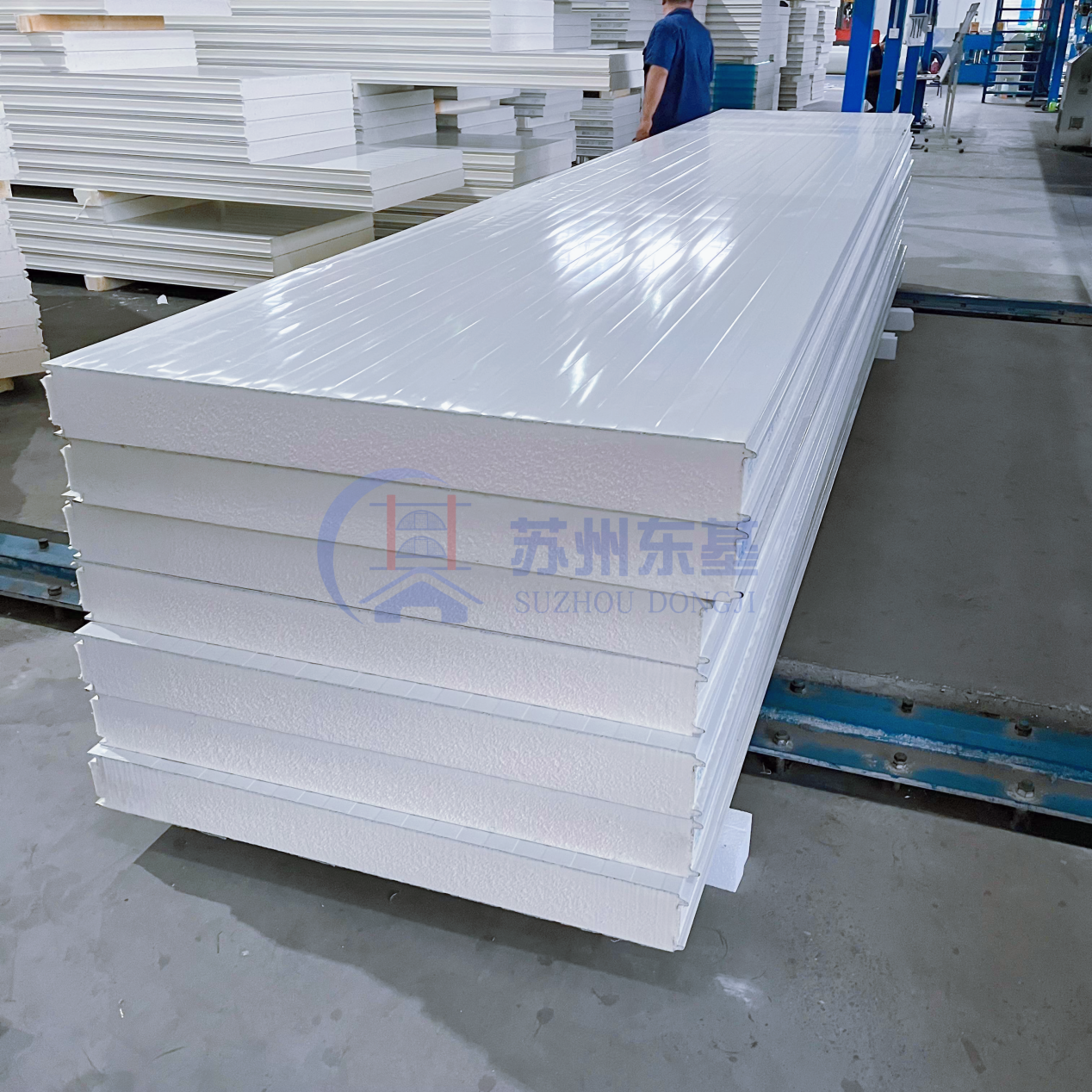

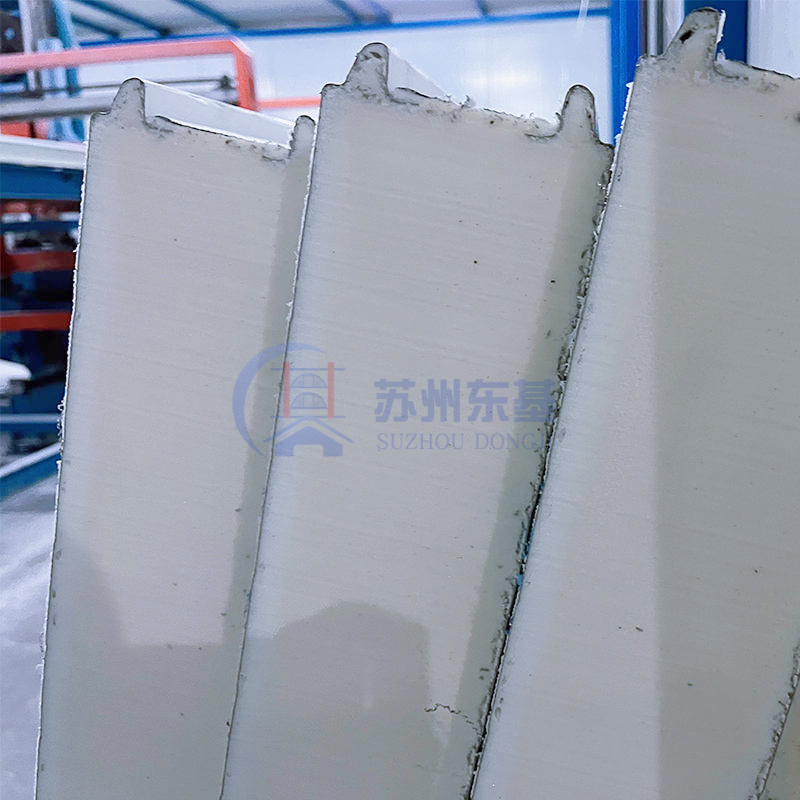

3. Polyurethane (PU) Wall Panels

Polyurethane (often abbreviated as PU) wall panels are recognized as the high-performance option in modular housing. With a closed-cell foam core, PU panels offer superior thermal insulation—even better than EPS panels—thanks to their higher density and lower thermal conductivity. They also have strong water resistance, preventing moisture penetration that can lead to mold growth or structural damage, making them suitable for humid climates or coastal areas. While PU panels are slightly more expensive than EPS or rock wool alternatives, their long lifespan, durability, and energy-saving benefits make them a worthwhile investment for high-end modular houses or projects focused on long-term sustainability.

Choosing the right wall panel material depends on factors like local climate, budget, and safety requirements. By understanding the strengths of EPS, rock wool, and PU panels, homeowners and developers can make more informed decisions to build modular houses that balance performance, cost, and comfort.

Hot News

Hot News2025-09-06

2025-07-01

2025-07-02

2025-06-16

2025-05-28

2025-04-03